Partner with Axonsemi to transform your supply chain, procurement, and industrial operations through our proven BPE and Decision Support methodologies.

Contact Us TodayOptimize Supply Chain, Procurement, and Industrial Operations

- Why Us

- What We Offer

- Case Studies

We help semiconductor companies optimize supply chain, procurement, and industrial operations by combining deep industry experience with business process engineering and advanced decision support capabilities.

Our consultants have 60+ years of combined experience from top tier semiconductor companies in operations, procurement, logistics, industrial and process engineering.

- Deep domain expertise

- Operational + digital focus (blend of BPE + DS)

- Execution-focused (not just strategy decks — hands-on guidance)

- Global experience with regional/local relevance

- Our Approach

- Engagement Models

- Offering Framework

Our Approach

The semiconductor industry is undergoing massive transformation; we bring unique value by combining deep operational knowledge with modern digital practices.

Business Process Engineering (BPE)

Process Identification → Documentation → Improvement Opportunities → Training → Maintenance → Success Metrics and Reporting → Audit Support

Why do you need BPE

- Complex, multi-tiered supply chains cause delays & cost overruns.

- Manual, fragmented processes increase errors & inefficiencies.

- Traditional fixes only treat symptoms — BPE delivers systemic process redesign.

Who is it for?

- Semiconductor fabs and fabless companies needing quick visibility.

- Teams preparing for larger transformation projects.

- Backend OSATs and packaging facilities.

- Fabs during ramp-up or equipment retooling phases.

Decision Support (DS)

Need Identification → Decision Support Tool Prototyping → Documentation and Training → Maintenance and Audit Support

Challenges & Solutions

| Challenge | Our Solution |

|---|---|

| Long lead times | Streamline material and supplier flows |

| Spare parts shortages | Adjust stocking levels using predictive analytics |

| Siloed data, no visibility | DS dashboards and real-time KPIs |

| Excess inventory | Inventory optimization and sourcing redesign |

| Inefficient fab layout | Lean redesign and capacity modeling |

| Capacity planning | Decision support through capacity modeling |

Engagement Models

6 Week Rapid Diagnostic

A high-impact, fast-track diagnostic engagement designed to quickly identify bottlenecks and improvement opportunities in top underperforming logistics, procurement, or industrial engineering processes.

Project Based or Month-to-Month – Comprehensive Support

Execute the prioritized process improvements to transform semiconductor operations, delivering measurable business impact. Diagnose additional processes and execute improvements.

Offering Framework

Our consulting engagements are designed to assess and analyze existing or envisioned processes to identify inefficiencies, bottlenecks, and opportunities for improvement.

| Offering | Timeline | Objective | Outcome |

|---|---|---|---|

| Rapid Diagnostic | 6 Weeks | Quickly identify & prioritize process improvement opportunities | Clear roadmap with ROI case |

| Comprehensive Support | Project-Based / Month-to-Month | Redesign & embed new logistics processes | Measurable operational improvements |

- Logistics

- Procurement

- Industrial Engineering

Logistics

Rapid Diagnostic — What We Do

- Stakeholder interviews & cross-functional process mapping

- Analysis of process performance (service level, inventory, material flow, staffing, etc.)

- Pain point determination and root cause analysis

- Prioritized improvement roadmap & business case

Rapid Diagnostic — Deliverables & Benefits

- Current state logistics process map(s)

- Pain points & root cause summary

- Actionable roadmap with quick wins

- ROI projection & KPI impact forecast

- Fast turnaround to enable confident decision-making

Comprehensive Support — What We Do

- Process redesign in supply chain, sourcing, inventory & warehouse

- Digital workflow & automation recommendations

- SOP development & training

- Support for continuous improvement & change management

Comprehensive Support — Deliverables & Benefits

- Redesigned, streamlined logistics processes

- Digital tool & KPI dashboard recommendations

- SOPs, training materials, and capability building

- Sustained improvements in process efficiency and effectiveness

Client Impact / Success Metrics

- Improved service level (material available when ordered)

- Increased inventory turns

- Reduced manual interventions & errors

- Improved supply chain agility & responsiveness

Procurement

Rapid Diagnostic — What We Do

- Conduct stakeholder interviews and map end-to-end top underperforming procurement process(es) (requisition to PO)

- Analyze procurement data: cycle times, approval delays, supplier lead times

- Identify root causes of bottlenecks, manual work, and rework

- Develop prioritized procurement process improvement roadmap and business case

Rapid Diagnostic — Deliverables & Benefits

- As-is map of top underperforming procurement process(es)

- Pain points and root cause summary

- Prioritized improvement roadmap with quick wins and medium-term projects

- ROI forecast and supplier risk mitigation strategies

- Executive summary to align stakeholders

Comprehensive Support — What We Do

- Redesign procurement workflows to eliminate delays and approvals bottlenecks

- Identify opportunities to automate procurement processes (purchase order creation, supplier tracking, and approval routing)

- Develop SOPs and train procurement teams

- Implement continuous improvement cycles and change management practices

- Diagnostics and comprehensive support for additional process(es)

Comprehensive Support — Deliverables & Benefits

- Redesigned procurement process(es), documentation and recommendations for digital workflows

- PO system improvements and supplier performance dashboard recommendations

- SOP manuals and targeted training programs

- Regular progress and KPI impact report definition

Client Impact / Success Metrics

- Procurement cycle time reduction

- Reduction in manual purchase orders and approvals

- Improved supplier on-time delivery rates

- Enhanced visibility into supplier performance and risks

- Lower procurement-related costs and supply chain disruptions

Industrial Engineering

- Capacity Modeling

- Productivity Management

Rapid Diagnostic — What We Do

- We analyze your current capacity modeling capabilities and determine what existing capacity modeling tools need improvement and/or what new capacity tools are needed

- Using your operational process and equipment data, and loadings forecasts, we create examples of recommended modeling tools.

Rapid Diagnostic — Deliverables & Benefits

- Capacity modeling tool status and needs

- Capacity modeling tool examples and roadmap

Comprehensive Support — What We Do

- Capacity modeling tool creation and validation

- Capacity tool documentation and training

Comprehensive Support — Deliverables & Benefits

- Sustainable documented capacity modeling tool

- Forward-looking analysis of production loadings vs. capacity

Client Impact / Success Metrics

- Identification of equipment needs (capital or dedication changes)

- Improved WIP and cycle time management

Rapid Diagnostic — What We Do

- We gather detailed data on yield metrics, defect logs, tool performance, and process flowcharts.

- Using advanced statistical techniques and data analytics, we pinpoint critical issues in the photolithography and etching processes, identifying tool performance variability and environmental factors as significant contributors to yield fluctuations.

Rapid Diagnostic — Deliverables & Benefits

- SPC Implementation

- Yield Improvement Plan

- Lean Manufacturing Integration plan

Comprehensive Support — What We Do

- Tool Qualification Protocols

- Training Programs

- Pilot Testing

Comprehensive Support — Deliverables & Benefits

- Performance Monitoring metrics

- Feedback and Optimization loop

Client Impact / Success Metrics

- Yield Rate Increase

- Defect Rate Reduction

- Cycle Time Reduction

- Tool Uptime improvement

- Logistics

- Procurement

- Industrial Engineering

Case studies are based on our consultants' experience

Logistics – Critical Materials Management

+Assess existing critical materials management processes and tools. Identify opportunities to use predictive analytics to optimize inventory levels by setting forward-looking stocking levels and aligning lead-time-based purchase order deliveries with production needs. Adjust existing or develop new tools to provide improved tactical decision support to proactively manage deliveries and lead-times from existing suppliers or begin sourcing from alternative suppliers if necessary.

Who is it for?

Fabs and ATs with critical materials inventory

Fabs and ATs looking to better manage their critical materials

What you get:

- Assessment of critical material management process

- Identification of process gaps and improvement opportunities

- Improved/New decision support tools (Excel, size limited, scalable)

- Executive presentation with findings and recommendations

Duration:

6–8 Weeks Pilot Project, 4–6+ Months Comprehensive Support

Impact:

Provided buyer/planners at a mature wafer fab with improved process and tactical decision support tools to better manage critical indirect materials. Chemical, gas, and target lead-times and inventory control improved significantly. Regular updates and reviews of the tactical decision support tools highlighted future inventory shortfalls as well as overages, giving buyers sufficient time to proactively manage purchase order delivery dates and lead-times to optimize inventory levels on an ongoing basis.

Logistics – Warehouse Capacity Management

+Assess existing processes and tools used to manage warehouse capacity for storage of spare parts, direct, and critical indirect materials. Identify opportunities to use predictive analytics and supplier relationships to align internal and external warehouse capacity with production needs.

Who is it for?

Fabs and ATs with spare parts, direct, and critical indirect inventory

Fabs and ATs looking to improve warehouse capacity management

What you get:

- Assessment of current warehouse capacity management process

- Identification of opportunities to optimize capacity and utilization

- Recommended decision support tools (Excel, size limited, scalable)

- Executive presentation with findings and recommendations

Duration:

6–8 Weeks Pilot Project, 4–6+ Months Comprehensive Support

Impact:

Worked with the direct materials procurement team of a major semiconductor company to properly understand wafer storage space requirements and predict future capacity needs for a warehouse supporting multiple wafer fabs ramping simultaneously. Provided inputs to the capital justification process for the required warehouse expansion to be completed in time to support production ramps.

Logistics – Supply Chain Assessment

+Map existing supply chain management process(es) to comprehend complex interactions between all internal and external participants. Identify process gaps and provide improvement recommendations. Determine KPIs and identify reporting needs to successfully monitor processes moving forward.

Who is it for?

Fabs and ATs looking to improve existing supply chain processes

What you get:

- Assessment of current/envisioned process

- Identification of process gaps and improvement opportunities

- Recommendation of KPIs and associated reporting

- Executive presentation with findings and recommendations

Duration:

6–8 Weeks Pilot Project, 4–6+ Months Comprehensive Support

Impact:

Mapped and reviewed existing spare parts repair process at a mature wafer fab where repairs were a consistent problem—either because expensive new parts had to be bought instead of repaired ones, raising costs, or because new parts were obsolete.

Identified and closed process gaps caused by lack of monitoring and coordination. Established KPIs and reporting to monitor repairs consistently.

Repair service levels improved from 70–80% to above 90%, often reaching 100%, and morale increased as the process became more effective.

Logistics – Spare Parts Inventory Management

+Assess existing spare parts inventory management processes and tools. Identify opportunities to use predictive analytics to optimize inventory levels by setting forward-looking stocking levels based on historical spare parts usage at known production levels. Establish regular review process to ensure stocking levels are aligned with demand-driven forecasts.

Who is it for?

Fabs and ATs with spare parts inventory

Fabs and ATs looking to align spare parts inventory with production

What you get:

- Assessment of inventory management process

- Identification of process gaps and improvement opportunities

- Improved decision support tools (Excel, size limited, scalable)

- Executive presentation with findings and recommendations

Duration:

6–8 Weeks Pilot Project, 4–6+ Months Comprehensive Support

Impact:

Determined future stocking levels for a combined spare parts warehouse for multiple fabs using predictive analytics based on historical usage and production levels.

Calculated ramp-appropriate stocking levels, allowing all fabs to ramp simultaneously with minimal operational impact.

Procurement Case Studies

Procurement – Supplier, Cost, and Risk Management

Assess existing procurement processes and tools. Identify process gaps and opportunities to improve supplier reliability, lead times, and quality, achieve cost reductions, lower supply chain risks, and improve regulatory compliance.

Who is it for?

Fabs and ATs with internal procurement operations

Fabs and ATs looking to improve procurement processes

What you get:

- Assessment of procurement processes

- Identification of process gaps and improvement opportunities

- Improved decision support tools (Excel, size limited, scalable)

- Executive presentation with findings and recommendations

Duration:

6–8 Weeks Pilot Project, 4–6+ Months Comprehensive Support

Impact:

During worldwide quartz and silicon carbide supply shortages, tightened supplier relationships and improved supply chain controls with multiple suppliers to fully understand lead-time changes, ensure ongoing supply of critical parts, and lower costs by avoiding expedite fees.

Audited a chemical distributor warehouse to lower warehouse safety risks from weather events. Established intermediate stocking agreements with distributors to provide back-up stock availability within a one-day delivery window, reducing risk of delays.

Industrial Engineering Case Studies

- Capacity Modeling

- Productivity Management

Assess existing capacity modeling capability and create a static capacity model based on customer equipment sets, process flows, and expected incoming material volumes to identify needed equipment, process, and operational changes.

Who is it for?

Fabs and ATs with limited or no capacity modeling capabilities

Fabs and ATs looking to better manage capacity and operations

What you get:

- Assessment of current capacity modeling capabilities

- Identification of capacity modeling opportunities

- Creation of prototype capacity model (Excel-based, scalable)

- Executive presentation with findings and recommendations

Duration:

6–8 Weeks Pilot Project, 4–6+ Months Comprehensive Support

Impact:

A static fab capacity model was created and used to determine capabilities for handling wafer loadings, justify capital projects, evaluate process changes, and maintain model input accuracy for continuous improvement.

At an OSAT site, a capacity model identified equipment needs, reduced uncontrolled WIP build-up, and improved understanding of throughput and process flow accuracy.

Client Profile

Example client profile – A leading semiconductor manufacturer specializing in advanced node technologies, experiencing challenges in maintaining consistent yield rates and optimizing production efficiency.

Client's Specific Goals

- Achieve Stable Yield Rates: Reduce yield variability, particularly in sub-micron processes, to ensure consistent product quality and output.

- Increase Throughput: Enhance process efficiency to increase overall production throughput and meet market demands.

- Standardize Tool Qualification: Implement robust tool qualification protocols to minimize production variability and reduce rework costs.

Client's Challenges

- Yield Variability: The client faced significant fluctuations in yield rates, particularly in sub-micron processes, leading to substantial losses in output and profitability.

- Process Inefficiencies: Frequent tool downtimes and extended cycle times were identified as key issues, delaying production schedules.

- Tool Qualification Issues: Inconsistent tool qualification processes led to variations in production quality, resulting in increased rework rates and additional costs.

Project Phases and Execution

Phase 1 – Diagnostic Assessment

- Data Collection: We gather detailed data on yield metrics, defect logs, tool performance, and process flowcharts. This comprehensive data collection allows us to identify the root causes of yield variability and inefficiencies.

- Root Cause Analysis: Using advanced statistical techniques and data analytics, we pinpoint critical issues in the photolithography and etching processes, identifying tool performance variability and environmental factors as significant contributors to yield fluctuations.

Phase 2 – Strategy Development

- SPC Implementation: We design and implement a Statistical Process Control (SPC) framework, customizing control charts for the client's specific processes. This framework enables real-time monitoring and early detection of process deviations.

- Yield Improvement Plan: We develop a comprehensive yield improvement plan, focusing on optimizing process parameters, enhancing tool maintenance schedules, and establishing stricter quality controls.

- Lean Manufacturing Integration: We introduce lean manufacturing techniques, including value stream mapping and kaizen workshops, to identify and eliminate waste. A 5S system is implemented to improve workplace organization and efficiency.

Phase 3 – Implementation and Training

- Tool Qualification Protocols: We revise and standardize tool qualification protocols, ensuring consistent and reliable tool performance. This includes developing rigorous testing and calibration procedures.

- Training Programs: Our team conducts training sessions for the client's engineering and production staff, covering SPC, lean manufacturing principles, and best practices for tool operation and maintenance.

- Pilot Testing: We implement a pilot program to validate the new processes and protocols in a controlled setting, making necessary adjustments before full-scale deployment.

Phase 4 – Monitoring and Continuous Improvement

- Performance Monitoring: We establish continuous monitoring systems to track key performance indicators (KPIs) such as yield rates, defect densities, and tool uptime. Regular performance reviews are conducted to assess the impact of the changes.

- Feedback and Optimization: We create a feedback loop with the client's team to address any emerging issues promptly and continually optimize the processes based on real-time data.

Results and Impact

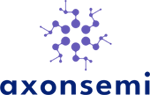

Yield Improvement:

The client achieved a 20% increase in yield rates within six months, significantly reducing scrap and rework costs.

Figure 1 — Yield Rates Improvement (Month 1–12)

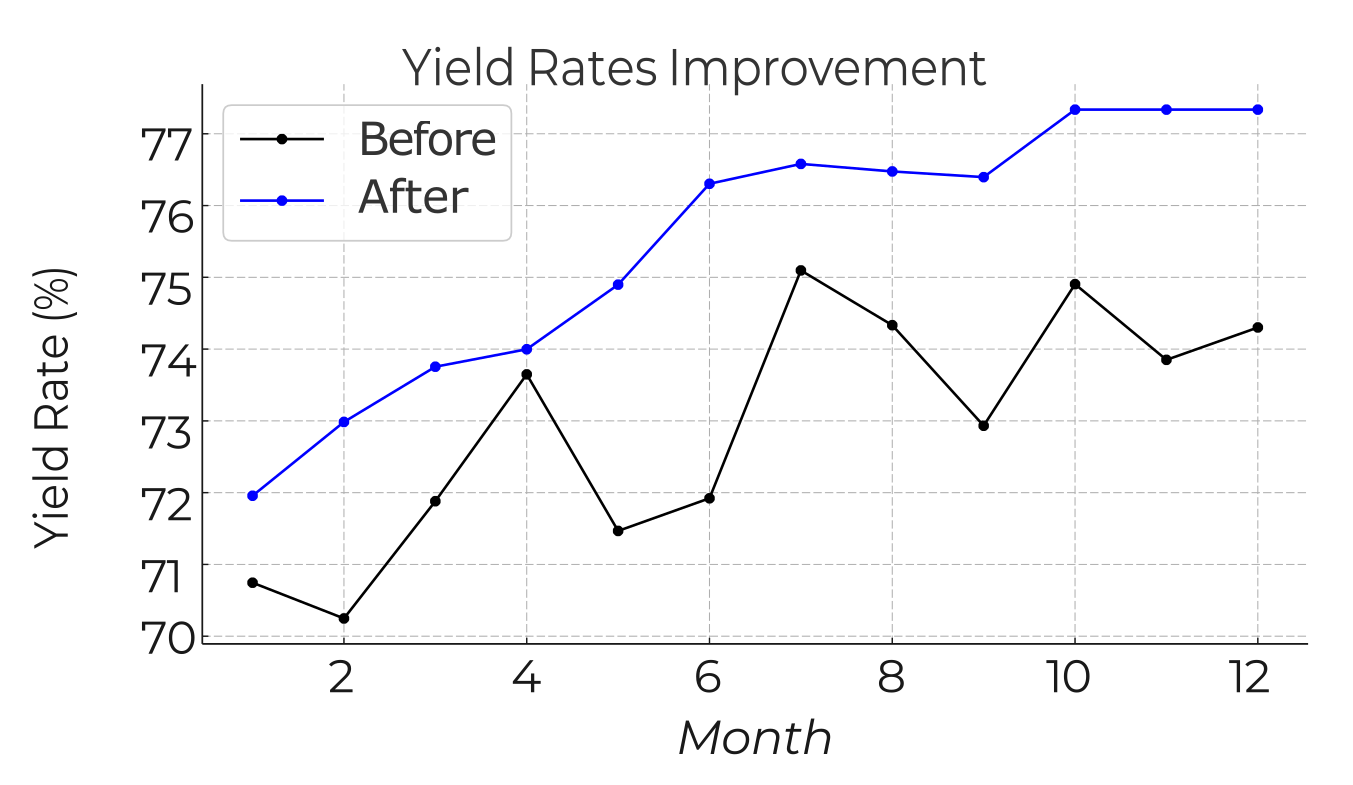

Defect Rate Reduction:

The client saw a notable reduction in defect rates, particularly in critical process steps, enhancing overall product quality and reliability.

Figure 2 — Defect Rates Reduction (Before/After)

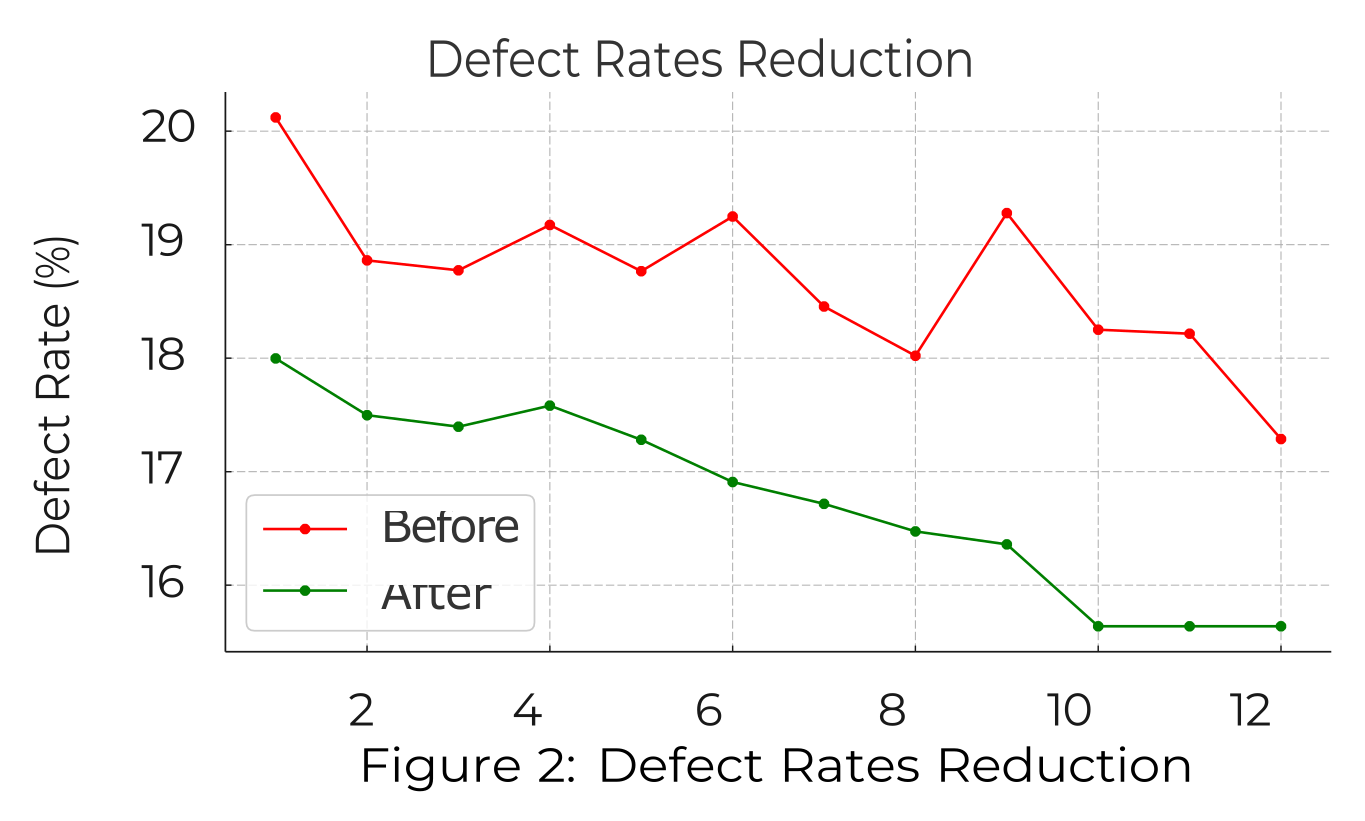

Process Efficiency:

The implementation of lean manufacturing practices resulted in a 15% reduction in cycle times, accelerating the client's time-to-market for new products.

Figure 3 — Cycle Times Reduction (Month 1–12)

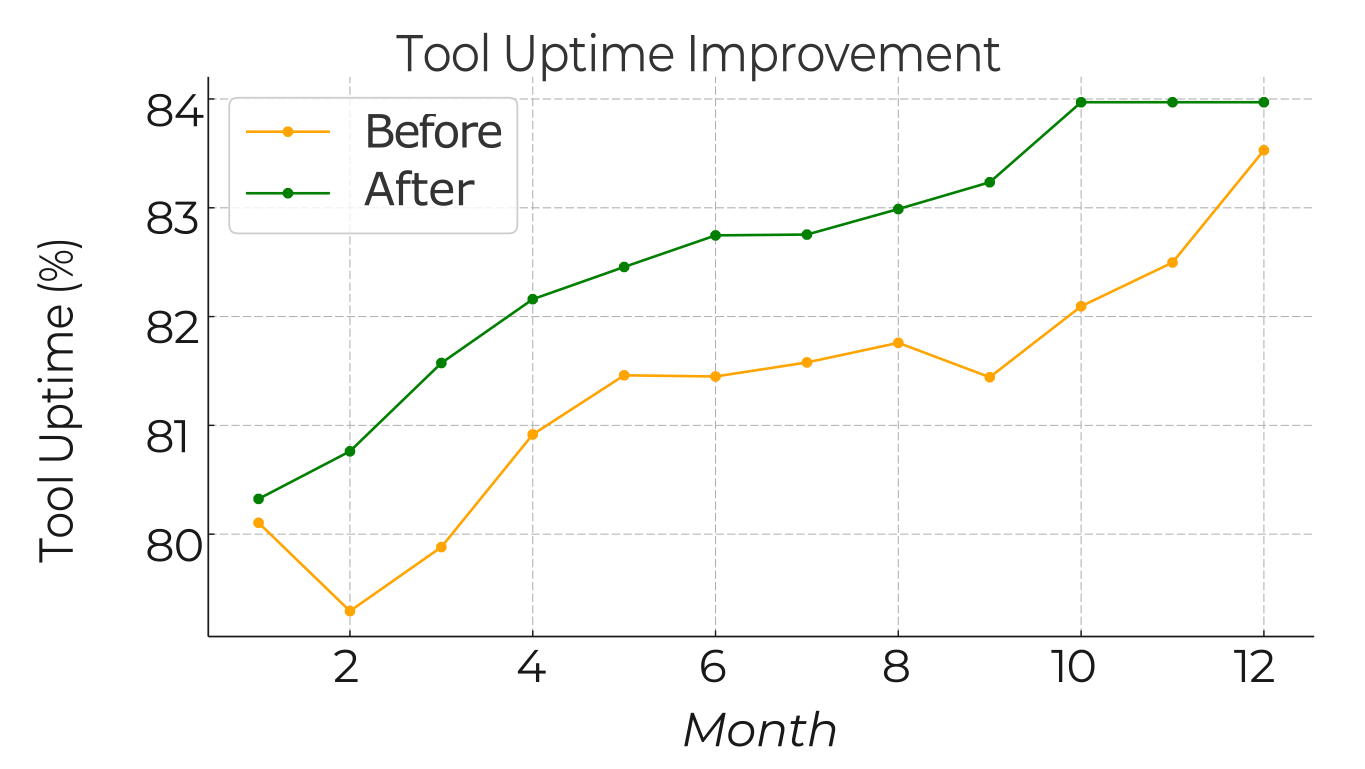

Tool Uptime:

Improved tool maintenance and standardized qualification protocols led to a 12% increase in tool uptime, enhancing overall production capacity.

Figure 4 — Tool Uptime Improvement (Month 1–12)

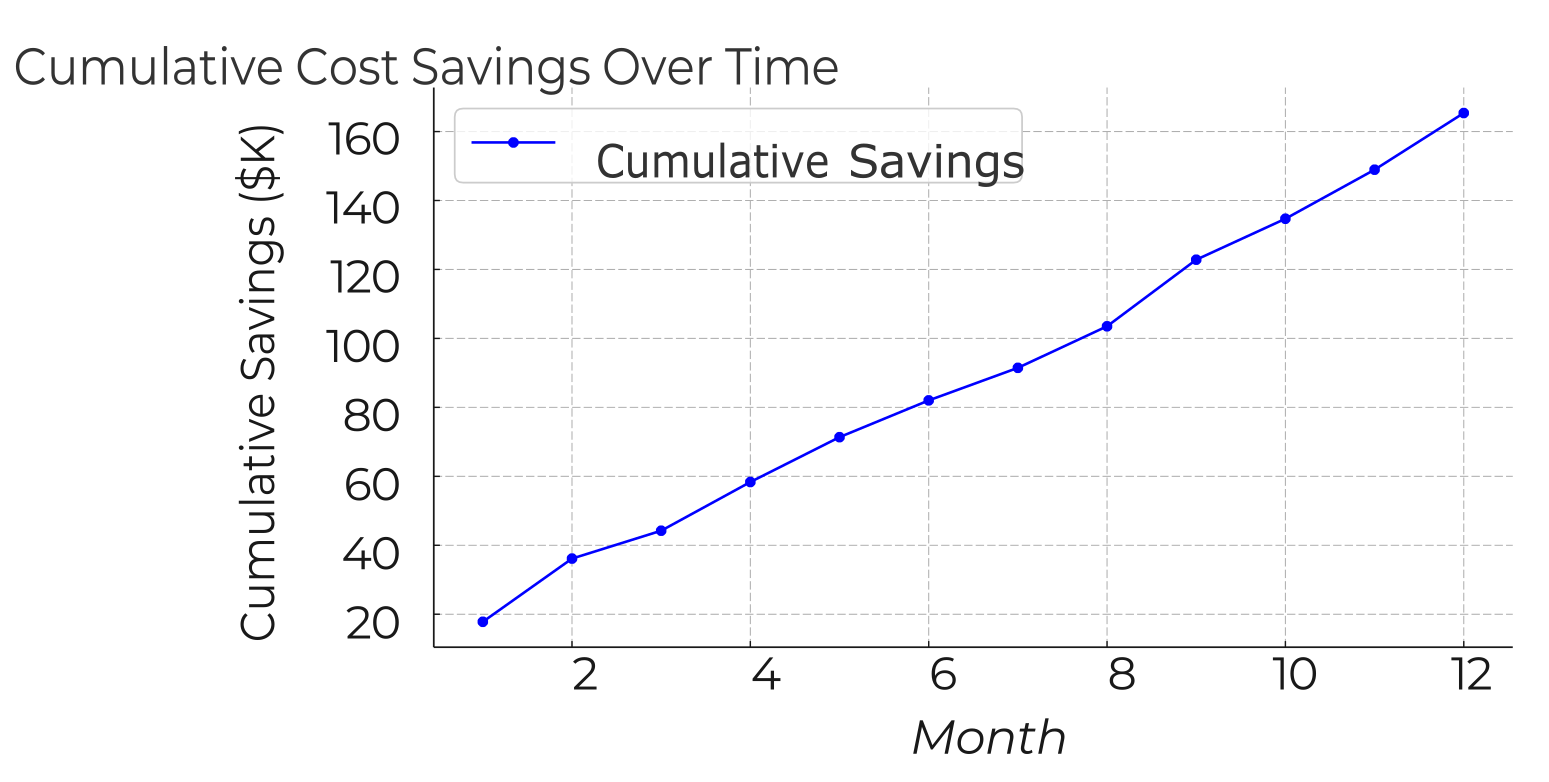

Cumulative Cost Savings:

Continuous cost savings are realized as a result of improved yield, shorter cycle times, and increased tool uptime.

Figure 5 — Cumulative Cost Savings Over Time

Client Feedback

The client expressed high satisfaction with the engagement, particularly appreciating the tailored solutions and proactive support throughout the project. Clear communication and effective training were highlighted as key factors in the successful adoption of the new practices.

Conclusion

This case study demonstrates Axonsemi's ability to significantly enhance yield stability and process efficiency in semiconductor manufacturing. By aligning strategies with the client's specific goals, measurable improvements were achieved in yield, throughput, and tool reliability, fostering a strong partnership for future growth.